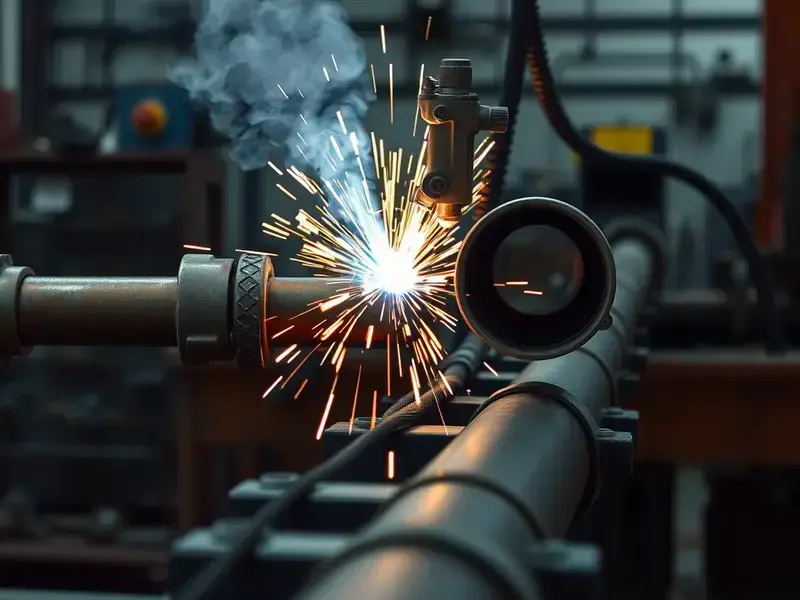

Professional Pipe Welding

Certified pipe welding solutions for industrial, commercial, and residential applications across Northwest Arkansas.

Pipe Welding Services

Precision Pipe Welding for Every Application

Pipe welding demands specialized skills and certifications. At B & M Muffler, our certified welders have extensive experience with all pipe materials and welding processes, ensuring leak-free, code-compliant connections every time.

From small-diameter plumbing pipes to large industrial pipelines, we bring the same level of precision and attention to detail to every job. Our shop is equipped to handle projects of various scales, from quick repairs to complete pipeline installations.

We maintain certifications and follow industry best practices for safety and quality. When you need pipe welding done right, our team delivers results that meet or exceed expectations.

AWS Certified

Certified pipe welders

Multiple Processes

TIG, MIG, and Stick

All Materials

Steel, stainless, copper

Code Compliant

Meet local standards

Applications

Pipe Welding Capabilities

We handle pipe welding across multiple industries and applications with expertise and precision.

Industrial Piping

Process piping, hydraulic lines, and industrial systems. Heavy-wall pipe welding for demanding industrial environments with high-pressure requirements.

HVAC Systems

Ductwork, refrigerant lines, and heating system pipes. Clean welds for efficient air and fluid flow in commercial and residential HVAC systems.

Plumbing

Water lines, sewer pipes, and gas lines. Residential and commercial plumbing repairs and installations with durable, leak-free connections.

Oil & Gas

Pipeline welding for oil, gas, and petroleum applications. Specialized welding for energy sector requirements with proper certification.

Construction

Building infrastructure piping, fire suppression systems, and utility connections. Code-compliant welds for new construction and renovations.

Heavy Equipment

Hydraulic lines, fuel lines, and exhaust systems for trucks, tractors, and construction equipment. Repairs and custom installations.

Materials & Processes

Expertise in Multiple Welding Methods

Different applications require different welding techniques. Our welders are certified in multiple processes to ensure optimal results for each project.

TIG Welding (GTAW)

Precision welding for thin-wall pipe and stainless steel. Creates clean, high-quality welds with excellent appearance. Ideal for sanitary applications and cosmetic welds.

Best for: Stainless steel, thin-wall pipe, sanitary applications

MIG Welding (GMAW)

Fast, efficient welding for thicker pipe materials. High deposition rates make it ideal for production work and thicker wall pipe applications.

Best for: Carbon steel, thick-wall pipe, production work

Stick Welding (SMAW)

Versatile process for outdoor and field work. Can handle dirty or rusty materials and challenging positions. Great for repairs and maintenance.

Best for: Field repairs, outdoor work, heavy equipment

Pipe Sizes

Capacity & Specifications

Our pipe welding capabilities span a wide range of sizes and specifications to meet diverse project requirements.

Size Range

- • Small diameter: 1/2" to 2" tubing and pipe

- • Medium diameter: 2" to 6" standard pipe

- • Large diameter: 6" to 12" heavy pipe

- • Custom sizes available upon request

Wall Thickness

- • Thin wall: Schedule 5, 10, 40

- • Standard: Schedule 40, 80

- • Heavy wall: Schedule 160, XXH

- • Up to 1" wall thickness

Not sure what you need? Our experts can help you determine the right specifications for your project.

📞 Call for ConsultationNeed Pipe Welding Services?

From small repairs to large installations, our certified welders are ready to handle your pipe welding needs.